New And Old? Mercedes-Benz Has Some Interesting Ideas About Vehicle Manufacturing

Mercedes-Benz recently announced a plan to make vehicles more “sustainable” and a portion of it pertained to bringing back some of the ways it used to build automobiles. However, suggesting that this is a complete return to traditional automotive manufacturing would be a gross misrepresentation.

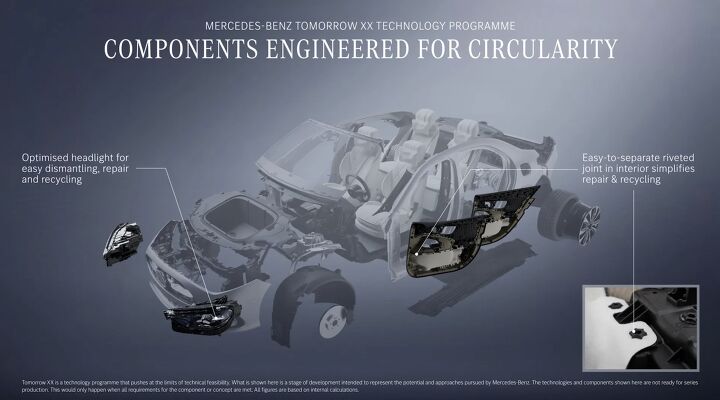

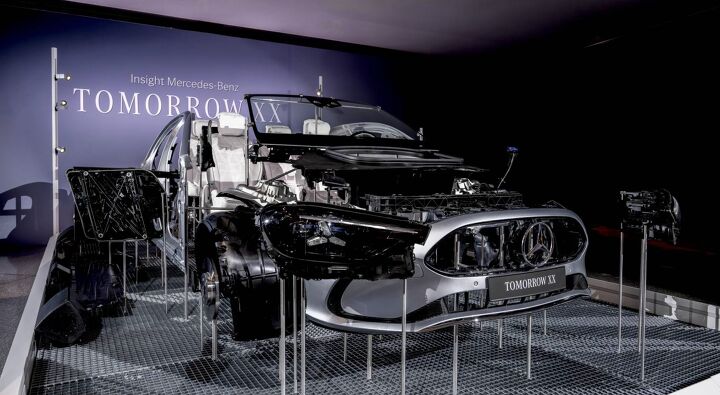

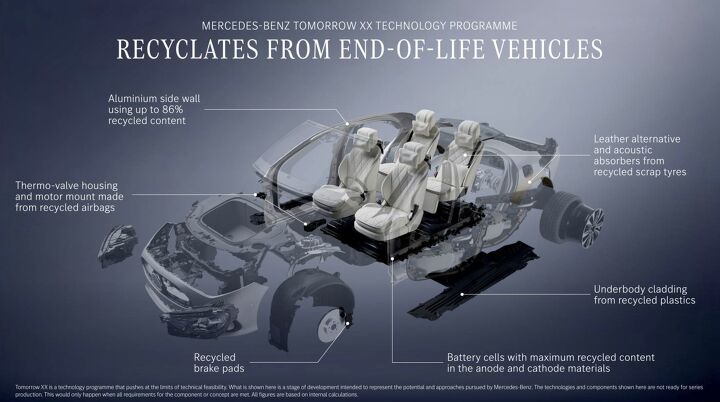

The scheme has been dubbed the “ Tomorrow XX technology program” and is focused on finding a way to blend innovation with an extensive list of environmental objectives — starting with the design phase.

According to the automaker, this means incorporating new ideas with some traditional ones that had been done away with. Mercedes-Benz stated that it would like to use more recycled plastics, ideally with the materials stemming from retired automobiles to create “circularity” that serves environmentalism.

Some of you are undoubtedly falling asleep already. However, similarly included in that was at least some level of thought given to parts replacement. Headlamps have become a favored example your author often points to when needing to showcase the perils of modern vehicle innovation. Unlike older headlamps, which only required a simple bulb swap that could be done by practically anybody in just a few minutes, modern units are an absolute chore to service.

While today’s LED units are supposed to last longer and assuredly offer bright illumination, they also frequently require someone to dismantle the front of their vehicle to service. Even then, the units can’t always have the requisite parts changed out. They may need a total replacement, which makes them both time and money intensive vs their predecessors — which is to say nothing of the additional complications created by way of the Controller Area Network (CAN bus) systems.

Mercedes-Benz has suggested that at least some portions of the headlight should be more easily replaceable, suggesting that the theory could (and would) be applied to other vehicle components.

From Mercedes-Benz:

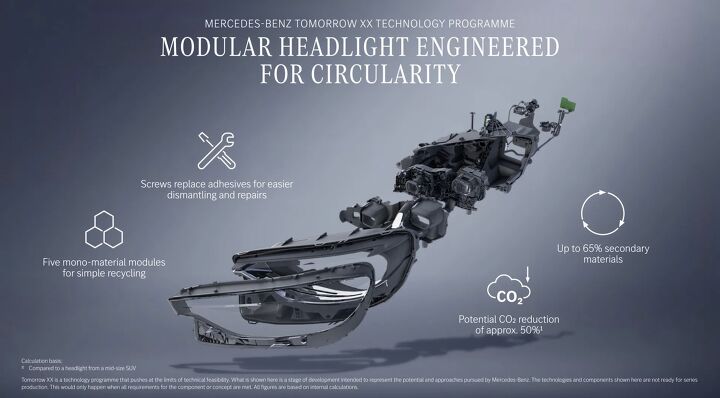

Mercedes-Benz is working to change the design of highly complex components to make these quick and easy to disassemble into individual parts. A promising Tomorrow XX research project is a recyclable headlight. The various components such as the lens, cover trim and frame, housing and electronics are joined with fasteners rather than glue (today’s standard practice). As a result, the headlight can be separated into individual components with ease and without damage. This means individual components can be replaced, making a modern headlight repairable for the first time. Following a stone chip, for instance, there is no need to replace the entire headlight, just the lens. For customers, this could make repairs more efficient in future. The longer service life of headlights could also help conserve resources and minimize carbon emissions.

The headlight concept is also designed to be better for recycling. Individual modules are each made of only one material to ease sorting and to be highly efficient to recycle. Looking to the future, this mono-material design should make it possible to use more recycled material and source a large part of this from old headlights. The proportion of secondary materials could potentially be almost doubled compared to today’s headlights, while carbon emissions could be reduced by nearly 50 percent.

The idea that less of the vehicle would be held together by glue is probably music to most people’s ears. Components that have been attached using nuts and bolts should be far easier to replace. This potentially adds to the longevity of vehicles, shrinks repair costs, and may even reduce the likelihood of something being deemed a total loss after receiving relatively minor damages.

But adhesives do still have their place. High quality adhesives can actually help minimize rattling as a vehicle ages and improve structural rigidity if properly utilized. Glues can also be used in places where bolts are impractical or costly. However, they can also break down over time — particularly if they’re off poor quality and exposed to extreme variances in temperatures. In the best cases, high-quality glues are smartly used in tandem with mechanical anchor points.

Material quality was another topic of discussion in Mercedes’ Tomorrow XX research project. As part of the environmentalism angle, the automaker suggested that plastics could be recycled from older vehicles to be put into new models. This is fine in theory. But there are some drawbacks.

Reclaimed plastics are typically not as strong as virgin plastics that are created directly from petrochemicals sourced from the ground. The issue is that recycled plastics have already been repeatedly exposed to head cycling, resulting in a more brittle molecular structure. The upside is that they’re cheaper to use and should (theoretically) be better for the environment. But they’re typically not as durable and may also pose additional health risks now that we’re becoming aware of the dangers of microplastics.

Still, we’ve gotten a lot better at manipulating petrochemicals. Many of the recycled plastics used today are stronger than the virgin plastics from decades past. However, modern virgin plastics still tend to be stronger overall.

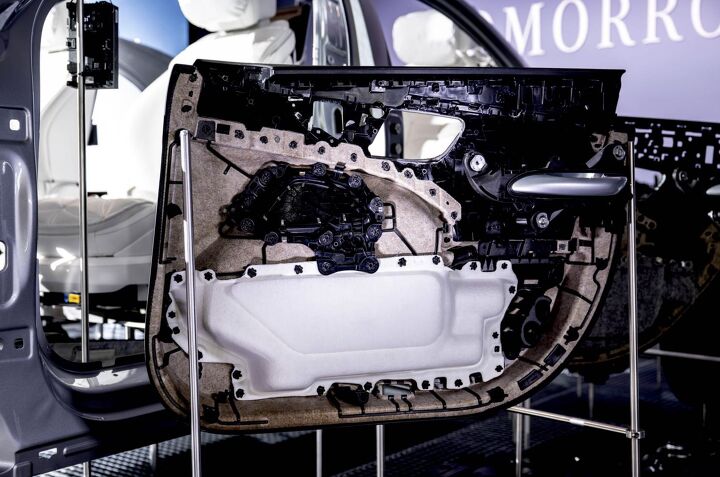

Mercedes also suggested that fusing select components together could be done via a mix of ultrasonic welding (melting plastics via intense vibrations) and leaning on plastic rivets. The former would effectively do the same thing as traditional adhesives while the latter would be a cheaper, lightweight alternative to metal bolts. In fact, your car probably already uses a number of them to secure the fabric in your trunk or to keep the wheel well in place.

The automaker also went into great detail on how to make recycled plastics more feasible for automotive use, acknowledging that there was a limit to how much you can recycle plastic before it becomes unfit for purpose.

“For a number of interior components, Mercedes-Benz has developed a sandwich composite system that consists of only one plastic: recycled PET,” stated the company. “The basis is a foam core with a bone-like structure. This reduces the weight of a door pocket by more than 40 percent compared to the previous material system made of primary plastic. The performance of the part remains the same. The outer layers consist of an innovative mixture of PET fibers, giving the composite system the necessary rigidity.”

These are already used by the automaker for wheel wells, door pockets, and some upholstery. But the new initiative seeks to broaden the use case, potentially even replacing “primary materials.”

We’ve seen many automakers swap out metal items for plastic ones in recent years. The arms holding up your doors or drunk may now be plastic. Some automobiles now even have plastic control arms and expansive underbody cladding. But it’s hard to say whether this is a bad or good thing.

If the plastic materials fail to break down before a metal component can rust away, then it’s hard to criticize. But if they lack the structural strength required to do the job or begin degrading prematurely, then this is a massive downgrade for the consumer. Sadly, newer models that have swapped to using plastics for those parts haven’t been on the road long enough for us to make any firm assumptions.

A lot of the above concepts have already been implemented by Mercedes-Benz and plenty of other automakers. What’s being suggested is for the automaker to push further in that direction in a way that can benefit the automaker, the customer, and the planet.

However, it’s extremely difficult to determine what constitutes a legitimate improvement and what’s just marketing hype. Car manufacturers have attempted to sell us on all kinds of things that either don’t offer any real utility to drivers of late. Meanwhile, there have been plenty of changes that probably were smart but saw poor implementation.

Environmentalism and technological evolution has likewise been used as a smokescreen to rationalize brand getting cheap on components. Despite being more material intensive (suggesting they’d have a larger environmental impact) touch screens have been leaned into because they’re less expensive for automakers to install vs buttons and open up the door to new revenue streams.

The same has been done with “recycled materials.” Interiors utilizing recycled plastics and “vegan leather” are often framed as luxurious and environmentally sound. But there are lingering questions on both fronts. In most cases, actual leathers are far more durable (if properly cared for), breathable, and come with fewer concerns regarding exposure to microplastics. By contrast, vegan leathers (which are made from plastics) are significantly cheaper to produce and implement in a variety of ways. Their potential to be recycled from waste plastics is another feature automakers like.

Other aspects of Mercedes’ plan revolved around improving metallurgy and finding additional ways of producing aluminum via renewable energy sources. Aluminum has replaced steel components on many vehicles over the years, primarily because it’s lighter weight and not prone toward rusting. But it’s fairly energy intensive, so Mercedes wants to reduce consumption while tapping suppliers that prioritize renewable energy sources. It likewise suggested introducing more recycled aluminum into vehicles.

There’s plenty more, including making new materials by extracting chemicals sourced from old tires. The automaker claimed that the resulting materials would offer a chemical makeup similar to virgin plastic and could be utilized as a “high-quality leather alternative” that would actually boast more tensile strength than the real thing and similar breathability.

It also concluded that old tires could be “manually recycled” (e.g. chopped up) and used for vehicle sound and vibration (NVH) reductions. The company is apparently in the midst of doing experiments on the topic and it makes sense. Compare an automobile with a lot of tire sidewall with something running low-profile tires and you’ll quickly find yourself learning how good an insulator tire rubber can be. It seems more than plausible that the material could be used to effectively insulate the cabin.

In fact, materials like Dynamat (used to line the interior of a vehicle to reduce interior noise and vibration) are actually composed largely of a butyl rubber mastic attached to a thin aluminum backer. The theory has already been tested and proven to be extremely effective.

Truth be told, a lot of what Mercedes-Benz is proposing here are not strictly novel concepts and have already seen broad use within the automotive industry. What the German company seems to be suggesting is leaning into those concepts even further with a mind to use recycled materials wherever possible (e.g. underbody cladding, seats, insulation, brake pads) to help offset waste.

What it doesn’t say (at least not directly) is that this should also help reduce materials cost while making itself look good with regulators and environmental advocates. This is all about creating an insular supply loop where waste materials can be repurposed into new vehicle components. However, it stated that the end goal would be to source materials from fossil-free plastics using biologically sourced materials.

We’re hardly chemical engineers, so our guess for when that’s realistically achievable is probably as good as yours. But Mercedes did acknowledge that it would have to take a mixed approach using both virgin and reclaimed materials in terms of manufacturing. That’s basically the status quo of any industry at all times and far less interesting to us than the company recognizing the need to make more components more easily replaceable.

We cannot speak with much authority to the latest advancements in petrochemical wizardry. But we do know that there’s nothing green (or convenient) about having to throw away large portions of a vehicle when a small component goes bad. If Mercedes is serious about tweaking vehicle assembly to make parts replacement easier for customers, that’s a win. But we’ll have to wait to see how it manifests on future production models before calling for a celebration.

“There can be no doubt that the overriding goal for all our products is to excite our customers while decarbonizing the automobile, driving down resource use and growing the circular economy," stated Olaf Schick, Member of the Board of Management Mercedes-Benz Group AG, Integrity, Governance and Sustainability. "Innovation is a key route to achieving this and Tomorrow XX makes clear the huge strides we are taking. Together with our suppliers and partners, we are leading the way and embedding sustainability deep into our operational business and along the entire supply chain.”

See? It's statements like that, made by people with job titles that include words like "Integrity, Governance and Sustainability," that often leaves me doubting. This makes me feel like whole shebang is just an effort to appease shareholders and regulators, not something designed to improve products for the end user. But I would very much like to be wrong.

[Images: Mercedes-Benz]

Become a TTAC insider. Get the latest news, features, TTAC takes, and everything else that gets to the truth about cars first by subscribing to our newsletter.

Consumer advocate tracking industry trends and regulations. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied, he pivoted to writing about cars. Since then, he has become an ardent supporter of the right-to-repair movement, been interviewed about the automotive sector by national broadcasts, participated in a few amateur rallying events, and driven more rental cars than anyone ever should. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and learned to drive by twelve. A contrarian, Matt claims to prefer understeer and motorcycles.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- MaintenanceCosts Looking forward to the ad-free Superb Owl.(Also some kind of football game which my hometown team is favored to win, despite having Joe Lunchpail as their quarterback.)

- Foaming Solvent Rivian, specifically the soon-to-be-available R2.

- 1995 SC From any analysis I've seen so far the big winner here is Tesla, which is ironic if that comes to pass lol

- Foaming Solvent "Governor Carney."As Eric Hoffer said, "Rudeness is the weak man's imitation of strength."

- Proud2BUnion BYD,NIO, and GYC!

Comments

Join the conversation

Less software, simpler designs, more robust materials = longer service life.

The car with the smallest environmental footprint is the one that is never built.

sounds like a load of garbage. These cars are overly complicated and recycle themselves while you drive. It will never happen as long as people are easily swayed by flashy cars.